Our value lies in having a work methodology that provides reliable results, helping in the decision-making process and the registration and commercialization of the products.

Innovation in the field of clinical and nutritional trials continuously requires better results in terms of quality. There is no innovation without research, and out of it, the activity of T&T would have ceased long time ago.

Since our inception more than 20 years ago, we have been dedicating ourselves to offering our clients excellence in the execution of the tests, following the requirements set out in the ISO 9001 Quality Manual and the Good Clinical Practice (GCP).

But… What is ‘’quality’’?

The International Organization for Standardization (ISO) defines it as “the set of characteristics of an entity, product or service that provides them with the ability to satisfy real needs”. Applying it to our scope of action: quality is the compliance with the invariability requirements established by our clients. We adapt to the test requirements, maintain impartiality, and guarantee reliable results. Proving that the products on market are safe and effective, we contribute to food safety.

T&T implements in all the trials the requirements set out in the ISO 9001-2015 and the Good Clinical Practice (GCP) from VICH program

Standard Operating Procedures, SOPs

We have the Standard Operating Procedures (SOPs) that describe the instructions to follow to ensure quality and the correct execution of our activity.

This practice has huge importance and impact on the sampling operations and the analytical procedures since they assure us that the sample is in ideal conditions for the analysis and that the integrity of the documents and media containing the data is preserved.

Our main objectives are to guarantee the reliability of the data and the trials results.

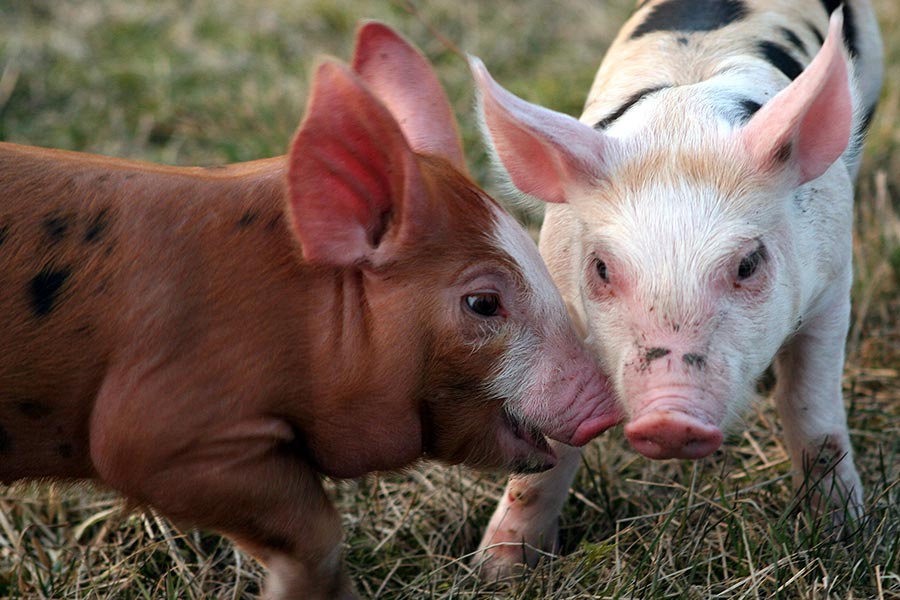

PIGLETS

San Esteban de Litera (Huesca)

FARM

30 m x 7 m (210 m²). Warehouse built with Ytong aerated concrete blocks

Concrete girders, joists and pillars (40x45cm)

660 piglets up to 25Kg.

PEN DIMENSIONS

2 lines of 30 pens each (60 in total) and a maximum of 11 piglets in each.

3 m2

Feed hopper and drinker. The feed is manually supplied to control daily consumption.

ENVIRONMENTAL CONTROL

The floor is entirely made of plastic slat injected with polypropylene with a 40% opening to ensure that the animals are kept clean and dry, and to reduce heat losses by contact and provide the necessary comfort and grip.

The partitions between pens are made of plastic panel.

The ventilation is automatic by windows of dimensions 1.20 x 1.80 m on both sides of the farm and the heating is automatic by means of electric heaters.

The lighting is naturally provided by the windows and by means of LED-type fluorescent lamps to provide a 16-hour day illumination.

POULTRY

Torrente de Cinca (Huesca)

FARM

4 m x 12 m

2.496 chickens

2 floors exposed brick

PEN DIMENSIONS

1.94 x 1.20 cm (2.3 m2)

Hopper: 45 cm diameter; 141 cm perimeter; 0.16 m2

Drinker: 33 cm diameter; 104 cm perimeter; 0.08 m2

96 pens with a maximum of 26 chickens in each

ENVIRONMENTAL CONTROL

EXAFAN RSP-GC programmer

4 outdoor and 1 indoor temperature probes

1 humidity probe

Automatic windows

Transverse forced ventilation: 4 fans 12000 m3 / h and 3 fans 32000 m3 / h

Heating: biomass stove + supplementary diesel cannon

Micro-sprinkler cooling

Illumination: 8 fluorescent tubes 1.5 m long

Water: Aragon and Catalonia channel. Treated on the farm with chlorine and acid. Ph and chlorine control

Principles for quality improvement on farms

Basing on studies carried out by official and private organizations, we implement a model that collects the best of each one and, above all, that it is useful, feasible, and provides information that allows the farms’ conditions improvement and the continuous evaluation.

Our team is highly qualified and trained. They maintain a unique criterial when assessing each point to analyze the situation and, later, indicate the necessary measures for the improvement of biosafety.

For the control and reduction of Salmonella (salmonellosis), we apply a series of preventive measures to avoid contamination by serotypes other than those we already have on the farm. We also enforce corrective measures that allow us to control and reduce its prevalence. Fields to control:

Location in front of other farms and accesses

Isolation measures (fencing, arch and disinfection gap, feed discharge, slurry loading, …)

Passive protection (footbaths, change of utensils according to production phase, …)

Entry of personnel (necessary hygiene measures)

Entrance of vehicles (certifications of cleaning and disinfection, access books, …)

Facilities and accommodation, as well as their maintenance

Water (disinfection and maintenance of tanks and drinkers)

Feed supply (certification against Salmonella), status and maintenance of silos and warehouses, …

Management and organization: By batches, unidirectional movement, regrouping of animals after weaning, …

Control of animal entries

Cleaning and disinfection protocol

Pests and other animals (control and preventive measures)

Documents and records (control plans, prerequisites, actions, …)

Veterinary supervision

Training

The parameters that we evaluate to determine the level of animal welfare on farms are those established in the European Welfare Quality ® protocol. Considered a benchmark in terms of welfare evaluation, it has an objective criterion recognized at European level:

All animals are provided with a balanced diet to prevent them from suffering malnutrition and/or thirst.

We adapt the facilities so that each species can socialize and express their own behavior patterns (for example, with the provision of toys). Our team makes sure they are free from physical or thermal discomfort (space to move freely and rest, adequate temperature…).

- We ensure their health in terms of hygiene, care, biosecurity, prevention, and control of diseases.

Our team has a personal and professional commitment regarding the treatment of animals, avoiding injuries, stress, and pain. We prevent them from feeling negative emotions such as fear, anguish, frustration, or apathy and promote positive emotions such as security and satisfaction.

The animal production sector pursues the maximum reduction of the use of antibiotics and their substitution by other quality products or production techniques that increase animals’ health, maintaining their productivity and well-being.

At T&T, we seek to know what the systematic and specific guidelines are used in each farm, as well as the number of antibiotics used per unit and its evolution over time after the application of new measures.